In 2021, empty shelves cost US retailers a staggering $82 billion in missed sales. Retailers lost an average of $1.4 billion every week simply because items weren’t in stock.

It’s clear that inefficient inventory control can have a huge impact on your business’s bottom line.

But not to worry! The right strategies and tools can help make sure your business always has the right number of products at the right times.

Keep reading to discover effective ways to optimize your inventory, avoid stockouts, and grab every sales opportunity that comes your way.

What is retail inventory management?

Retail inventory management is the process of systematically organizing and controlling a stock of products. The goal is to make sure there is enough stock to meet customer demand — but not too much.

In smaller businesses, the business owner or a manager oversees inventory. Larger companies may have specific roles, like an inventory control manager or warehouse manager.

Here is a simple breakdown of what inventory management includes:

Ordering stock: Deciding what and how much to order and when

Stock receiving and storage: Accepting, checking, and storing incoming goods

Inventory tracking: Monitoring stock levels and movement

Demand forecasting: Predicting future stock needs based on sales trends and market research

Replenishing stock: Ensuring stock levels are maintained to meet customer demand

Inventory auditing: Regularly checking inventory records for accuracy

Common inventory management terms

Understanding inventory management begins with knowing some crucial terms. Let’s explore key terminology often used in inventory management:

Stock-keeping unit (SKU): A unique identifier for each distinct product and service that can be purchased

Inventory turnover: A measure of how many times inventory is sold and replaced over a specific period

Backorder: An order for a product that is temporarily out of stock

Lead time: The time taken between placing an order and receiving it

Safety stock: Extra inventory held to prevent stockouts

Just-in-time (JIT) inventory: A strategy that involves receiving goods only when they are needed, thereby increasing efficiency and reducing waste

Demand forecasting: The process of predicting future customer demand based on historical data and market analysis

Inventory management across different business types

Your approach to keeping track of inventory depends on the type of business you’re running. Inventory management for small shops, for instance, will be different than it is for big chains.

Here’s a brief rundown of how inventory management typically works for five different business types:

Small stores: Are often manually managed with simpler systems, focusing on essential products. They only stock what is essential and popular to minimize costs.

Chain stores: Use more sophisticated inventory management software to coordinate different locations. They tend to have streamlined processes for bulk purchasing and maintaining consistent stock levels across stores.

Brick-and-mortar stores: Integrate inventory management with point-of-sale (POS) systems.

E-commerce businesses: Use e-commerce platforms with inventory management features.

Drop shippers: Rely on suppliers’ inventory management systems.

Why is inventory management important for your retail business?

Wondering about the importance of inventory management? Here’s why it matters and what you can gain from it:

Makes inventory tracking more efficient

Good inventory management enables business owners to keep track of their stock. Knowing what’s in stock, what’s running low, or what’s in surplus allows for better overall management.

Imagine a bookstore owner with an inventory management system. They can instantly check if a specific title is in stock, how many copies are available, and when they need to reorder. This helps prevent lost sales since only in-stock books will be available for customers.

Prevents overstocking and understocking

A well-managed inventory system means making sure you have just the right number of products — not too many and not too few.

Think of it like this: If you buy goods to sell, but they just sit there in your store or warehouse, that’s money you’ve spent that you can’t use for anything else. Plus, you might have to pay to store this inventory, especially if those products take up a lot of space or require a special type of storage.

On the other hand, if you don’t have enough of what your customers want, they simply can’t buy it from you.

Imagine someone coming to your store looking for something specific, but you’ve run out. They’ll probably be disappointed, and there’s a good chance they’ll go somewhere else to find it. This means you miss out on the sale. Not only that, but the customer might think twice before coming back — especially if the same thing has happened more than once.

Reduces shrinkage and employee theft

Good inventory management helps you keep a close eye on your products so you can spot and stop problems like shrinkage. Shrinkage is when goods disappear due to employee theft, shoplifting, or administrative errors.

If you don’t keep track of your inventory properly, you might not even notice these items are gone until it’s too late. That means you lose products you could have sold.

Minimizes discrepancies with vendors

Accurate inventory tracking means fewer disputes with vendors and suppliers around order quantities and deliveries.

For example, a restaurant manager who keeps accurate inventory records can quickly resolve disputes with suppliers over delivery shortages or billing issues, as they have precise data to back up their claims.

Imagine you run a restaurant and order 50 steaks from your supplier. But when the delivery arrives, you only get 40 steaks. If you haven’t kept track of your inventory, you might not be sure whether you ordered fewer steaks by mistake or the supplier made an error.

However, if you do have everything noted correctly, you can quickly check and say, “I ordered 50, but I only got 40.” This way, there’s no confusion, and you can sort the issue out with the supplier right away.

Offers insights into sales trends

Proper inventory management provides valuable insights into sales trends. Understanding what sells well and what doesn’t allows business owners to make informed decisions about what to stock, discontinue, or promote.

For instance, upon analyzing their inventory data, an electronics retailer might notice that certain models of laptops are selling faster than others. This insight allows them to stock more of the popular models and phase out the less popular ones, maximizing sales as a result.

If you don’t have a good system to keep track of your inventory, you’ll end up doing everything by hand. This means physically counting each item, writing those numbers down, and then trying to figure out what’s missing and what needs to be reordered.

This is a lot of work, and it can take up a lot of time that could be used for other tasks. It’s also easy to make mistakes. Maybe you count something wrong or forget to write something down. These issues can lead to more problems, like ordering too much or not enough stock — and both of these can result in cash flow issues.

The basics of retail inventory management

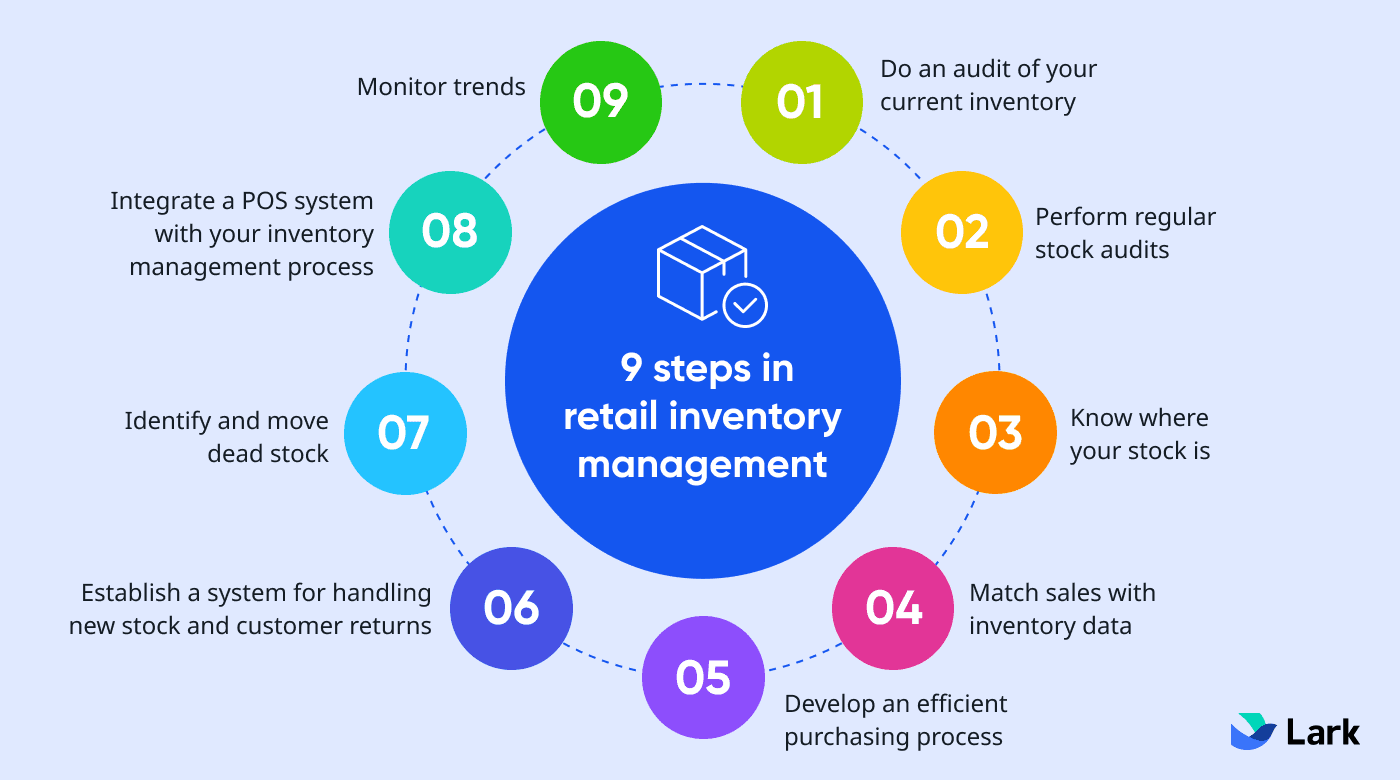

Below is a step-by-step guide to getting started with retail inventory management. We use the example of a clothing store to give you a holistic picture of where to start and how to maintain a successful inventory management system.

Step 1: Do an audit of your current inventory

First things first: You need to know what you have. For our clothing store, this means going through all shirts, pants, dresses, and, accessories and noting every detail. Each item gets a unique SKU that acts as an individual ID, helping you track everything from a medium-sized red cotton t-shirt to a single pair of blue jeans in size 32.

Step 2: Perform regular stock audits

Consistent checks are the backbone of inventory management. In the context of our clothing store, this might mean doing a complete stock count every three months.

Frequent counts help you keep track of what’s selling and what’s not. You’ll also have the opportunity to identify losses, whether due to theft, damage, or administrative error.

Step 3: Know where your stock is

If your clothing store operates both online and offline or has more than one location, you need to keep track of where each item in your inventory is located. In our clothing store, you can use a unique barcode to easily track a particular item, whether it’s in the storeroom, the warehouse, on the shop floor, or out for delivery to an online customer.

Step 4: Match sales with inventory data

It’s important to note which items are your bestsellers and which aren’t doing so well. In our clothing store, this could mean noticing that summer dresses are flying off the shelves while wool scarves aren’t.

This is where matching sales with inventory data comes into play. By regularly analyzing sales data and comparing it with current inventory levels, the store can make informed decisions about its stock.

You might order more of those summer dresses in additional styles or colors to capitalize on the trend. This decision isn’t just based on a hunch but is backed by concrete sales figures.

For those scarves that aren’t selling well, you have a few options. You could put them on sale to clear them out and make room for more in-demand items, or you could return them to the supplier or store them for the next winter season.

In some cases, if an item consistently doesn’t sell across multiple seasons, that might be a signal to discontinue stocking it altogether.

Step 5: Develop an efficient purchasing process

Ordering new stock for your store should work like a well-oiled machine. It involves setting reorder points — or reordering items based on how quickly they sell.

Using software to automate this reordering process can save time and minimize the chances of mistakes. For example, you might tell the software to automatically reorder jeans whenever you have only 10 pairs left.

Another way to optimize the purchasing process is to continuously evaluate your suppliers. This involves more than just finding the lowest prices — it’s about ensuring that the suppliers you work with are reliable and consistent and offer good terms.

Step 6: Establish a system for handling new stock and customer returns

Whenever new stock arrives, it’s not just about adding more items to the shelves. Each new delivery needs to be thoroughly checked for accuracy and quality.

Compare the delivered items against the order list to ensure that you’ve received the correct number of items. Then, check for any defects or damage. In the world of clothing retail, this could mean examining items for tears, incorrect sizing, color discrepancies, or other quality issues.

Once the stock is verified and checked for quality, it must be logged into the inventory system.

Similarly, handling customer returns effectively is crucial. This includes having a process for checking returned items and updating inventory records accordingly.

Step 7: Identify and move dead stock

Dead stock is inventory that isn’t selling. This is a problem because the longer stock remains unsold, the higher the storage fees get.

In our clothing store, you might see that last season’s fashion items haven’t sold, whether due to becoming obsolete or going out of fashion. Deciding what to do with these items — returning them to the vendor, selling them at a discount, or even donating them — is an important step in freeing up space and resources.

Step 8: Integrate a POS system with your inventory management process

When a POS system is integrated with inventory management, each sale, return, or exchange is immediately recorded and reflected in the inventory. For example, when a customer purchases a floral summer dress from our clothing store, the POS system instantly deducts this item from the inventory count.

This real-time tracking extends across all store locations, ensuring that inventory data is always up-to-date.

Step 9: Monitor trends

Finally, keeping an eye on what’s trending is vital. For our clothing store, this might mean stocking up on more beachwear as summer approaches or bringing in more coats and scarves as winter nears.

By understanding sales trends, you can make more informed decisions on inventory.

4 retail inventory management best practices

Retail inventory management can be a tricky path to tread, but with the tried-and-true best practices below, you’ll have the tools you need to transform your inventory into a well-oiled machine.

1. Invest in the right software

Investing in specialized software is the best thing you can do for your retail business and its inventory.

Lark, an all-in-one collaboration and inventory management tool, revolutionizes the tedious process of tracking inventory accurately and streamlines business processes in your retail operations as a whole. It provides real-time updates on stock levels, reducing the chances of inaccuracies.

Lark makes it easy for your warehouse employees to submit inventory changes using their phones, ensuring accurate counts of your inventory in real time. The automations and formulas in Lark Base also allow your business to automatically calculate and report on inventory status before it’s too late.

Last but not least, Lark’s all-in-one nature enables businesses to not only track inventories but also act on them, where discussions on inventories, procurement processes, as well as budgeting can all be managed in the same place.

Lark also automates tasks like stock counting and data entry, freeing up staff to focus on more important tasks like customer engagement and sales.

There’s also Lark’s Order & Inventory Management Template, which provides a clear view of what’s being sold and ordered by automatically calculating the remaining items in stock based on orders placed. With real-time calculations and restock reminders, Lark helps keep your retail inventory in stock — and your business thriving.

2. Choose the right inventory management method

Businesses have varying needs and operational models, which means that the effectiveness of an inventory management method can significantly differ between them. This variation calls for a tailored approach to inventory management, where each business selects the method that best aligns with its specific requirements and challenges.

Here are some inventory management methods:

Just-in-time (JIT): Involves keeping minimal inventory and receiving goods only as needed. This reduces storage costs but requires accurate demand forecasting.

First In, First Out (FIFO): Ensures that older stock is sold first, reducing the risk of obsolescence. This is especially important for perishable goods.

Last In, First Out (LIFO): The opposite of FIFO, is often used for non-perishable goods.

Economic order quantity (EOQ): A formula that calculates the ideal order quantity to minimize ordering and holding costs.

Retail stores, especially those with a fast product turnover, might benefit from methods like JIT to reduce storage costs or FIFO to ensure that older stock is sold first — which is crucial for perishable goods.

3. Establish KPIs

Key performance indicators (KPIs) provide measurable values that can help you evaluate and improve the effectiveness of your inventory management practices. Regularly monitor KPIs and use reporting tools to keep an eye on metrics.

KPIs might include the following:

Stock turnover: Measures how quickly inventory is sold

Backorder rate: Indicates how often items are out of stock and back-ordered

Inventory turnover days: The average number of days it takes to sell and replace inventory

Sell-through rate: The percentage of inventory sold within a specific period

Order lead time: The amount of time between placing an order and receiving the stock

Shrinkage rate: The rate of inventory loss due to theft, damage, or administrative error

4. Use safety stock

Safety stock is like a backup supply of products that a store keeps just in case. It’s extra inventory that’s there to help prevent the store from running out of items, especially when there are unexpected changes like more customers buying something than usual or delays in getting new stock from suppliers.

Having safety stock ready helps avoid a loss of sales due to empty shelves while you wait for new stock to arrive.

Retail audit FAQs

How do you track retail inventory?

To track retail inventory, use inventory management software combined with barcode labels and SKUs for each item. This setup allows for efficient tracking and management of stock levels in real time.

What are the 5 types of inventory?

The five types of inventory are as follows:

Raw materials: The basic, unprocessed materials used to manufacture products, such as metal, wood, or textiles

Work-in-progress (WIP): Items that are in the process of being manufactured but are not yet complete

Finished goods: Completed products that are ready for sale or distribution to customers

Maintenance, repair, and operations (MRO) supplies: Items that are used in the production process but are not part of the final product, such as tools, lubricants, and cleaning supplies

Safety stock: Extra inventory kept on hand to prevent stockouts caused by unforeseen demand or supply delays

What are the 4 types of inventory management?

The four types of inventory management are as follows:

Just-in-time (JIT): This method focuses on receiving goods only as they are needed in the production process, reducing inventory costs.

Economic order quantity (EOQ): EOQ is a formula used to determine the ideal order quantity that minimizes both ordering and holding costs.

ABC analysis: This approach categorizes inventory into three groups (A, B, and C) based on importance and value, helping prioritize management efforts.

Days sales of inventory (DSI): DSI measures how long it takes for a company to turn its inventory into sales, indicating the efficiency of inventory management.

Maximize your retail inventory management with Lark

From keeping accurate track of stock levels to managing supplier relationships, retail inventory management has a lot of moving parts. But it’s a crucial process for maintaining the balance between supply and demand and driving business growth.

Lark simplifies and automates key inventory management tasks, leading to more efficient and error-free operations. Integrations with existing POS systems, e-commerce platforms, and other business tools for efficient inventory management will be coming out soon.

With Lark, inventory management isn’t just about numbers and data — it’s about gaining insights and making informed decisions to help businesses maintain optimal stock levels, even during the busiest seasons. With real-time stock updates and trend analyses, Lark ensures you’re always a step ahead in your business strategy.

Unlock the power of efficient inventory management by trying out Lark.